This is a report on what I learned working with the Scully algorithm for static deflection of a bamboo rod.

I've been dabbling off and on with deflection calculations for a couple years. I have zero mechanical engineering background. I came up with a few solutions that seemed reasonable but I never had any confidence in their correctness or robustness. They were similar to Scully's method, in that they used an iterative approach, small deflection theory and accumulating the deflection over short segments. But they were not sound. So I was interested in the simple algorithm Scully developed.

Problem 1. Implementation

I recoded the algorithm in Perl, my language of choice for quick and dirty. I discovered that the algorithm did not always converge. It would tend to oscillate between two extremes. Some particular tapers were problems, as were higher values of the force (weight) input. (I do not know if Scully had this problem or if MATLAB has some magic. Or maybe he chose his tapers and small forces carefully.) A little addition which automatically reduced the size of the oscillations solved that problem (details upon request). The algorithm does seem to break down for very large deflections (over 50% of rod length).

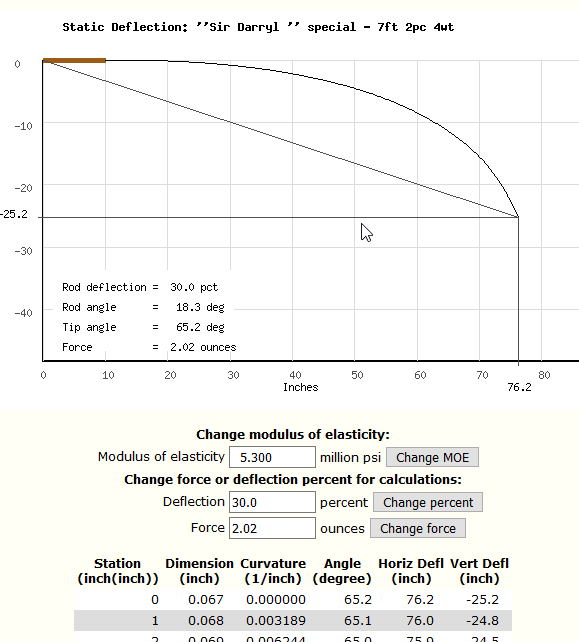

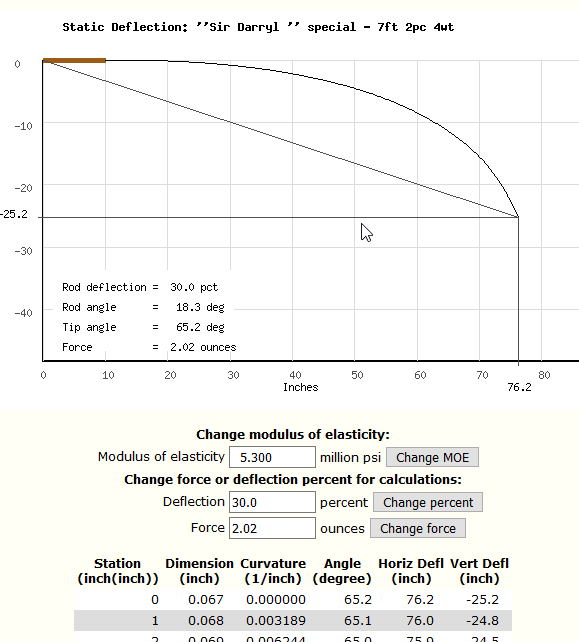

After some testing I decided to add it to my Hexrod program. The default assumes a MOE of 5.3 million PSI and deflects to 30 percent of the total rod length. The user can change the MOE and either the total deflection to solve for force or vice versa. Segment length is 0.2 inches, which is smaller than necessary, but execution time is only a fraction of a second. Output is a graph and a table. Like this:

Most deflection curves look pretty much alike; someone will need to use the tables for any sort of analysis. The Compare action in Hexrod gives two curves on a graph. Here are two 7.5 ft 5wt rods a (fast) Cross and a slow(Hardy):

The Hexrod program works for hex, quad or penta configurations, solid or hollow builds, and American or metric units. No doubt I will make some tweaks in the coming weeks. Someday I will work with Scully's code for large deflection. I have another working code for large deflection of an untapered beam that has a more detailed derivation, for comparison.

Problem 2: Dynamic Deflection

It turned out to be simple to adapt the algorithm to a somewhat dynamic deflection analysis. Here is the line in Scully's MATLAB code that computes the curvature:

Code: Select all

curv(i) = p* (X(n) - X(i)) / EI(i)

The numerator term is the moment. We simply substitute a dynamic moment such as

Code: Select all

curv(i) = (Sum from j=i+1 to n)(G * W(j) * (X(j) - X(i)) / EI(i)

W(j) is the total weight of the cast components for section j (bamboo+ferrule+varnish&guides+line in guides) and W(n) includes the weight of the line being cast. G is an force multiplier. These are all items included in Garrison's stress calculation, with G=4. I admit I borrowed this logic from Max's DynaRod.

Here is the dynamic deflection for the SirD taper casting 40 feet of DT4:

I will have to work with this for while before I release it for the unwashed masses of Hexrod users.

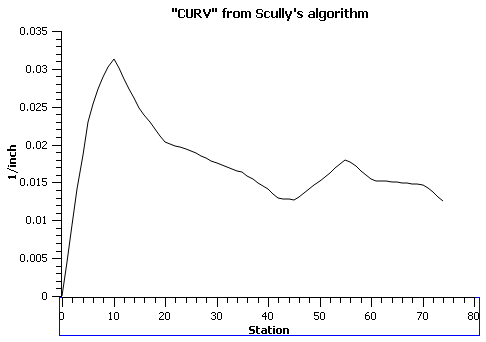

Problem 3: Curvature/Stress calculations

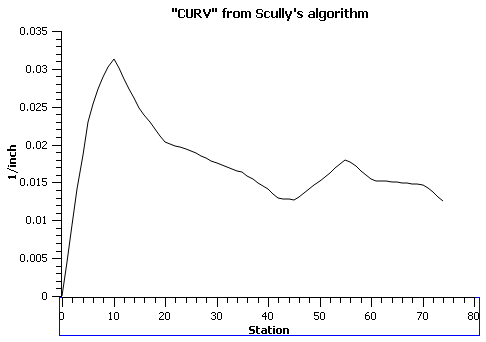

Scully's algorithm returns four vectors for n-1 segments: the deflection coordinates X and Y, the slope of the segments, and the curvature. The first three are intuitive, but the curvature looked interesting. (You can also calculate it yourself from the deflections.) I made a plot:

Even a blind pig finds the occasional acorn! That is the SirD stress curve, with a different vertical scale:

I guess I should have known this was coming; Scully says the curvature is the second derivative of deflection, and Henk mentioned that stress is the (a) derivative. I haven't worked out the scaling of the vertical axis; I assume it involves multiplying the curvature by the MOE in ounces per square inch. I will need to dig into this, unless some engineer wants to give me a hint.

What does this mean for application of deflection to rod design? First, if you have a deflection curve, you can calculate curvature and, with some assumptions about line weight, the taper. If you modify the curvature (say by stretching) and derive a new rod you are just modifying (stretching) the stress curve. This has been available in Hexrod for 20+ years. Second, is there really any advantage to working with deflection over stresses? For years people have been telling me that stress calculations are a lot of hooey and real taper design must be done with deflection. They are the same. Even if you add more factors to your deflection, you can probably add them to stress calculations.

I know this stuff is pretty elementary, and is nowhere near as complete as FEA, but I'm having a helluva good time playing with it.

--

Frank Stetzer